Optimizing the structure and design of industrial plants is essential for achieving operational efficiency, cost savings, and enhanced productivity in today's competitive industrial landscape. Digital modeling and simulation are potent tools that are revolutionizing this process. Industrial plant owners and operators can gain access to a number of advantages while optimizing their operations by utilizing cutting-edge software solutions like Autodesk Maya and Fusion 360. This article examines how digital modeling and simulation might enhance the design of industrial plants and processes.

Digital Modeling And Simulation Advantages:

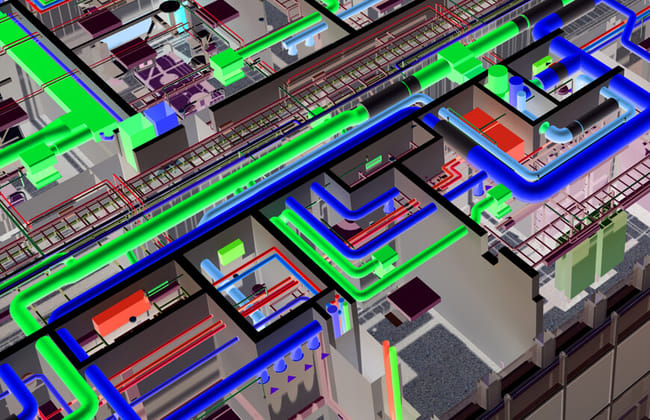

Enhanced Visualisation: Digital modeling makes it possible for stakeholders to see the plant architecture and process flow in a virtual setting, which improves decision-making and spatial connection comprehension.

Effective Resource Allocation: Simulation tools aid in the identification of bottlenecks, the optimal positioning of the equipment, and the streamlining of material flow, which results in effective resource allocation and enhanced operational effectiveness.

Cost savings: Plant owners can find opportunities for cost savings, waste reduction, and resource allocation by simulating various scenarios and examining the impact on productivity and resource utilization.

Increased Safety and Ergonomics: Digital modeling makes it possible to assess safety precautions, and ergonomic factors, and identify potential risks before they are physically implemented, creating better working conditions.

Streamlined Supply Chain Integration: Digital modeling and simulation allow supply chain activities to be seamlessly integ

What Points To Remember When Looking For Promo Codes?

Visit the official Autodesk website: To learn about current sales, exclusive discounts, or free trial offers for Autodesk Maya and Fusion 360, visit the official Autodesk website.

Authorized Resellers: Ask about special offers or bundles that include discount vouchers for software downloads from Autodesk's authorized resellers or partners.

Plans: Autodesk provides a number of subscription options for its software products. Find affordable membership solutions that meet your needs by exploring them.

Educational Licences: Autodesk frequently offers discounted or free licenses for educational reasons to students and educators. See if you are eligible for any grants or scholarships. After that, you are able to use Fusion 360 discount and make the payment.

Benefits Of Digital Modeling And Simulation In Industrial Plant Optimization

The optimization of industrial plants can benefit greatly from digital modeling and simulation. They improve visualization in the first place, enabling stakeholders to evaluate and comprehend the plant structure and process flow in a virtual setting. Better decision-making and spatial planning are made possible as a result. Second, simulation tools make it possible to locate bottlenecks while maximizing resource allocation, material flow, and equipment placement. Cost reductions and increased operational effectiveness are the results of this. Additionally, before physical implementation, digital modeling and simulation can evaluate safety precautions, take ergonomics into account, and detect potential risks, improving overall plant safety. Finally, they optimize supply chain efficiency by streamlining transportation, inventory management, and supply chain integration.

Overview Of Software And Tools For Digital Modelling

In order to optimize industrial plant layout and process design, digital modeling tools and software are essential. With the use of these technologies, users may build precise and lifelike digital models of the plant, facilitating effective planning, analysis, and optimization.

Autodesk Fusion 360 is a versatile 3D CAD, CAM, and CAE tool. It empowers users to create detailed plant layouts, assemblies, and simulations with ease. Additionally, Fusion 360 facilitates collaboration through its integration of cloud-based storage and offers a wide array of design optimization tools for seamless project development. For a discount on Fusion 360, you can also use the Autodesk discount and grab the exclusive discount.

AutoCAD Plant 3D is a specialized software designed specifically for plant design and layout purposes. It offers an extensive range of tools that empower users to create intelligent 3D models, produce accurate documentation, and foster seamless collaboration among project stakeholders. CAD software is also used by Tesla.

Dassault Systèmes CATIA is a powerful 3D modeling and simulation software widely used in various industries, particularly in plant design. It provides advanced capabilities for designing intricate layouts, optimizing processes, and simulating equipment performance.

Siemens NX, a comprehensive CAD/CAM/CAE software, offers a wide range of features for plant layout design, process simulation, and optimization. Its advanced tools allow for the evaluation of equipment placement, material flow, and overall plant efficiency.

Enhancing Safety and Ergonomics in the Plant Layout

Improving ergonomics and safety in the design of the plant is essential for the well-being of employees and the overall effectiveness of operations. Tools for digital modeling and simulation offer useful insights on how to improve ergonomics and safety measures. Operators can proactively mitigate risks prior to implementation by analyzing human-machine interactions, spotting potential dangers, and evaluating ergonomic variables, such as workstation design and material handling. Simulations can be used to make improvements to workflows, reduce repetitive labor, and improve the layout for easier accessibility and less physical strain. Industrial facilities may create a safer working environment, boost employee happiness, and boost productivity by putting a priority on safety and ergonomics.

Maximizing Efficiency And Performance Through Digital Optimization

In many businesses, digital optimization is a potent strategy for increasing productivity and effectiveness. Organizations may optimize processes, workflows, and resource allocation by using cutting-edge technology and tools including digital modeling, simulation, and data analytics. Through the discovery of bottlenecks, inefficiencies, and optimization opportunities through digital optimization, data-driven decision-making, and targeted improvements are made possible. Organizations can visualize, analyze, and iterate on many situations through precise modeling and simulation, which results in streamlined processes, lower costs, and more productivity. Businesses can maintain their competitiveness, adjust to shifting consumer needs, and achieve sustainable growth in today's dynamic and difficult environment by leveraging the power of digital optimization.

Conclusion

Digital modeling and simulation have transformed the optimization of industrial plant layout and process design. By harnessing the power of visualization, simulation, and analysis, operators can identify and rectify inefficiencies, improve safety, streamline logistics, and achieve cost savings. The integration of digital tools into the design and optimization process enables stakeholders to make informed decisions, reduce risks, and maximize overall plant performance. Embracing digital modeling and simulation not only enhances the efficiency of industrial plants but also paves the way for future advancements and innovations in the field.